Create safe, tidy and easily accessible work spaces for large and bulk items.

From timber packs, to piping, to scrap vehicles, we have a racking solution for you.

Customisable

Painted or Galvanised

Saves Space + Time

Up to 30 Tonnes Per Upright

Up to 2 Tonnes Per Arm

Cantilever racking maximises storage capacity, accessibility and presentation of large items. It is a flexible, bespoke solution that can provide high returns on investment through increasing productivity and easier stock management.

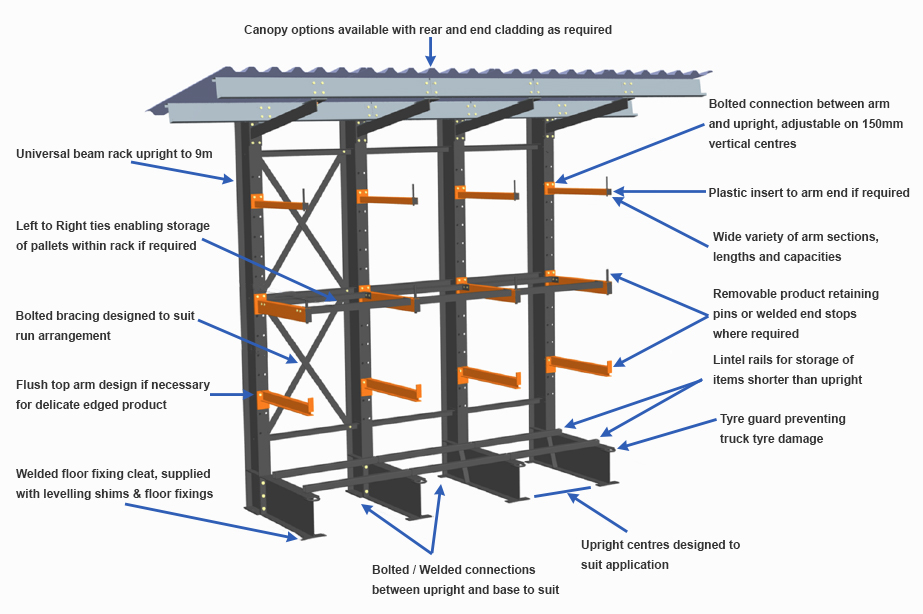

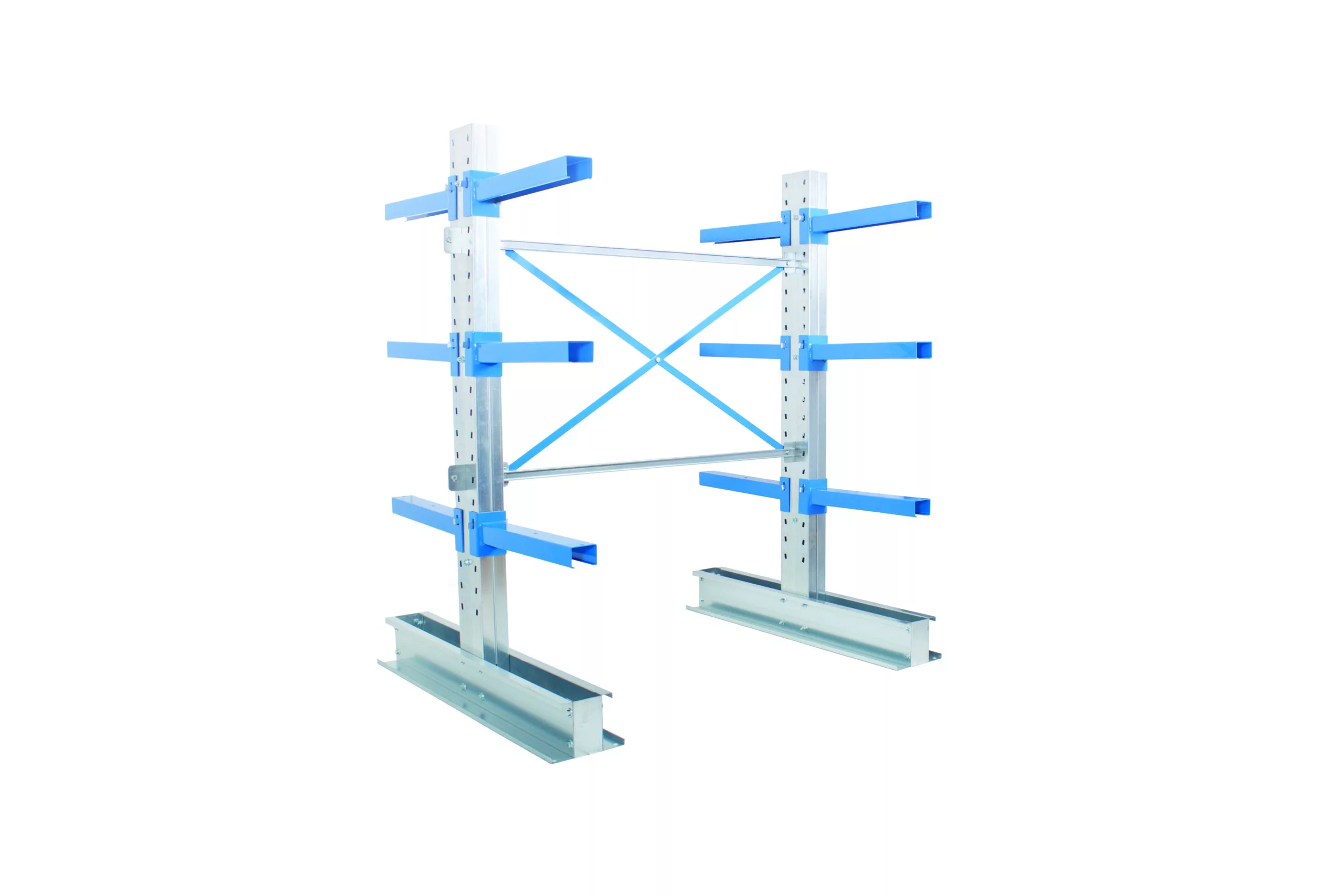

Cantilever racking consists of several core elements:

- Uprights: Columns

- Horizontal: Rear Bracing

- Horizontal: Arms

- Base: Bolted and Welded

The configuration of these elements dictates the loading ability of the units, with up to 30 tonnes per upright possible.

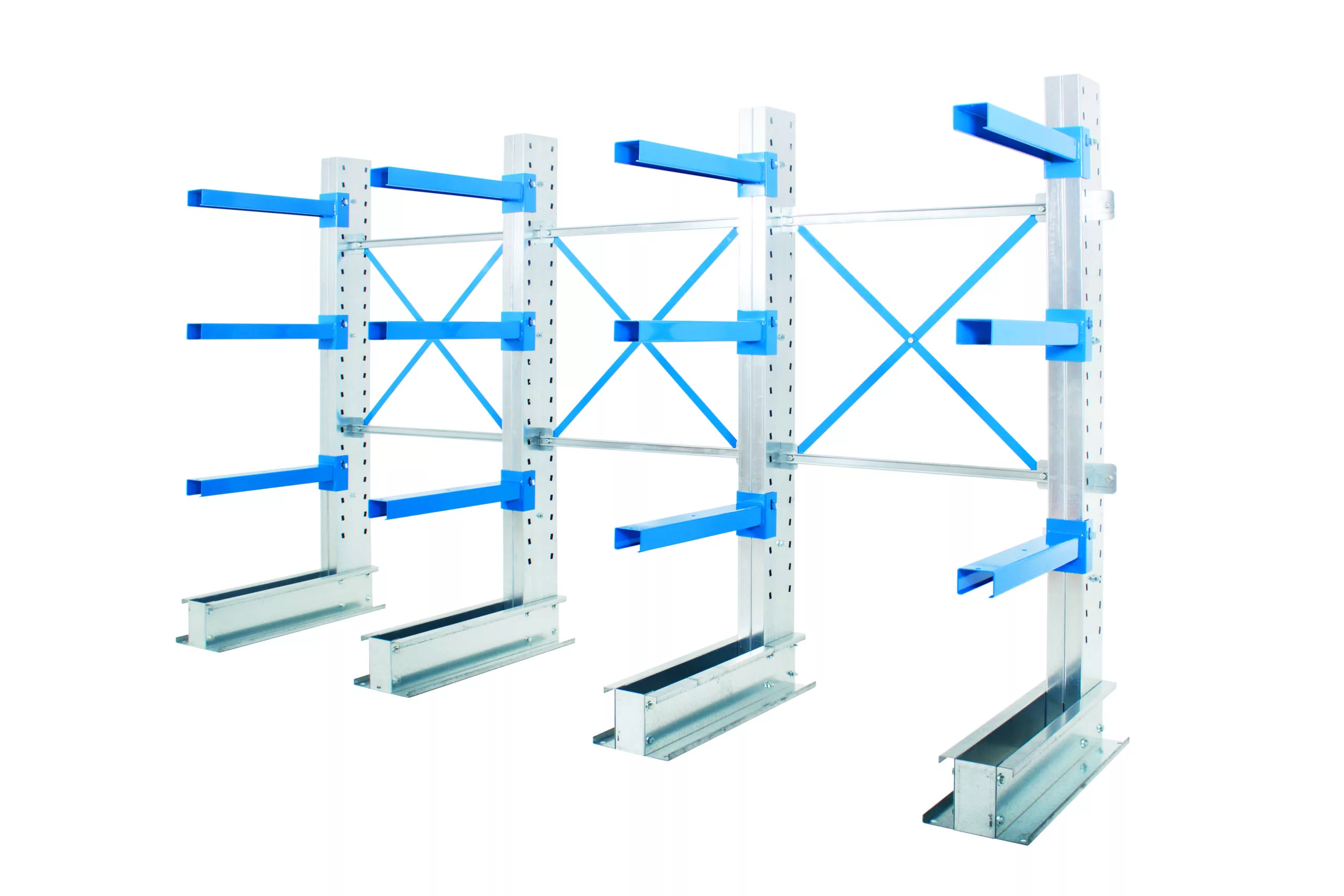

Racking can be either single or double sided.

Due to modular design, the racking can be extended by inserting columns at appropriate widths as necessary, creating large runs. This can be mirrored front and back, creating a double row for increased storage density.

Our heavy duty racking is designed to British Standards within the following limitations:

- Up to 10m High

- “Infinite” 3m wide bays

- Up to 2000mm arm length to carry 2 tonnes

- Up to 30 tonnes of product per upright

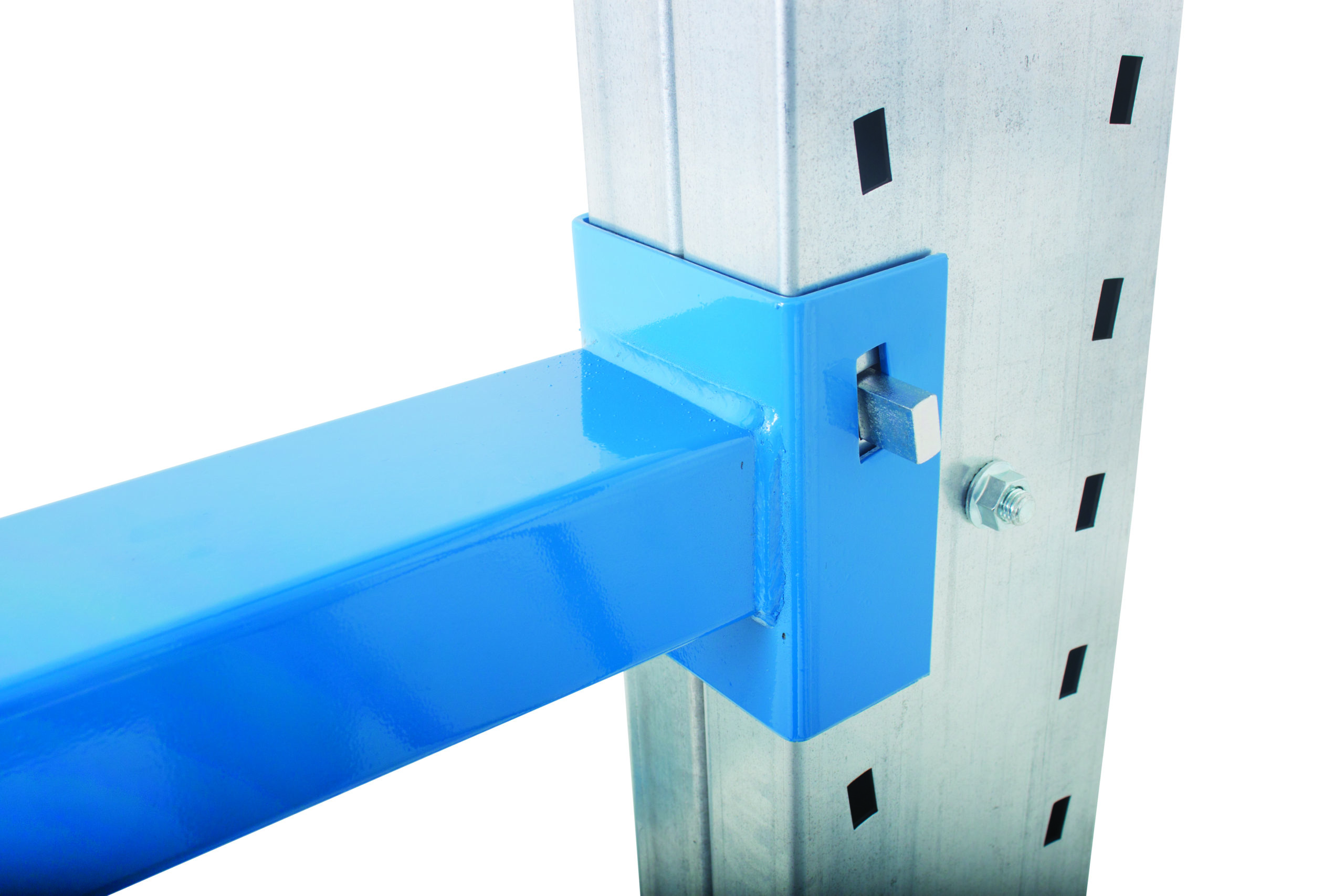

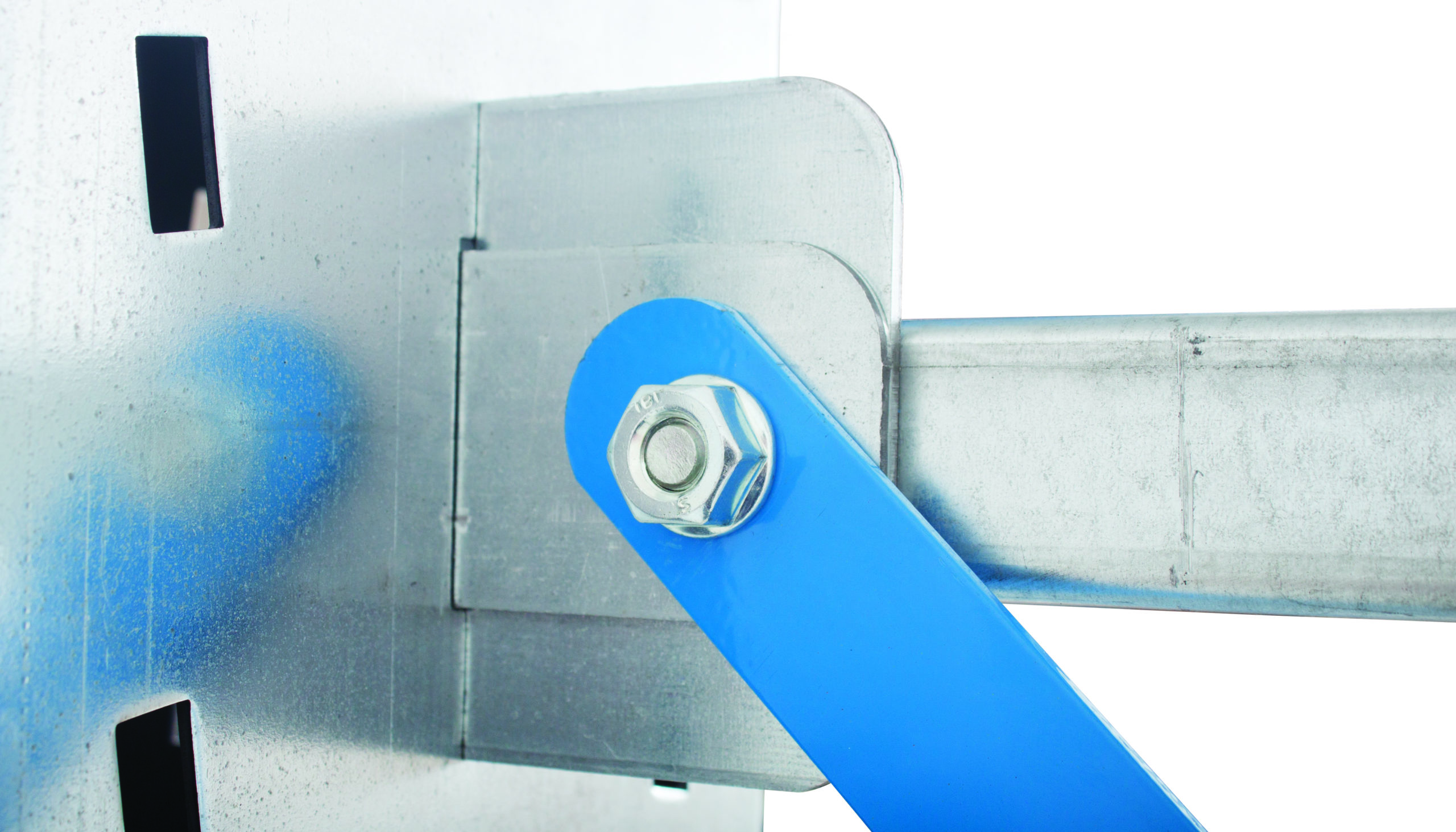

- Adjustable bolted arms every 150mm

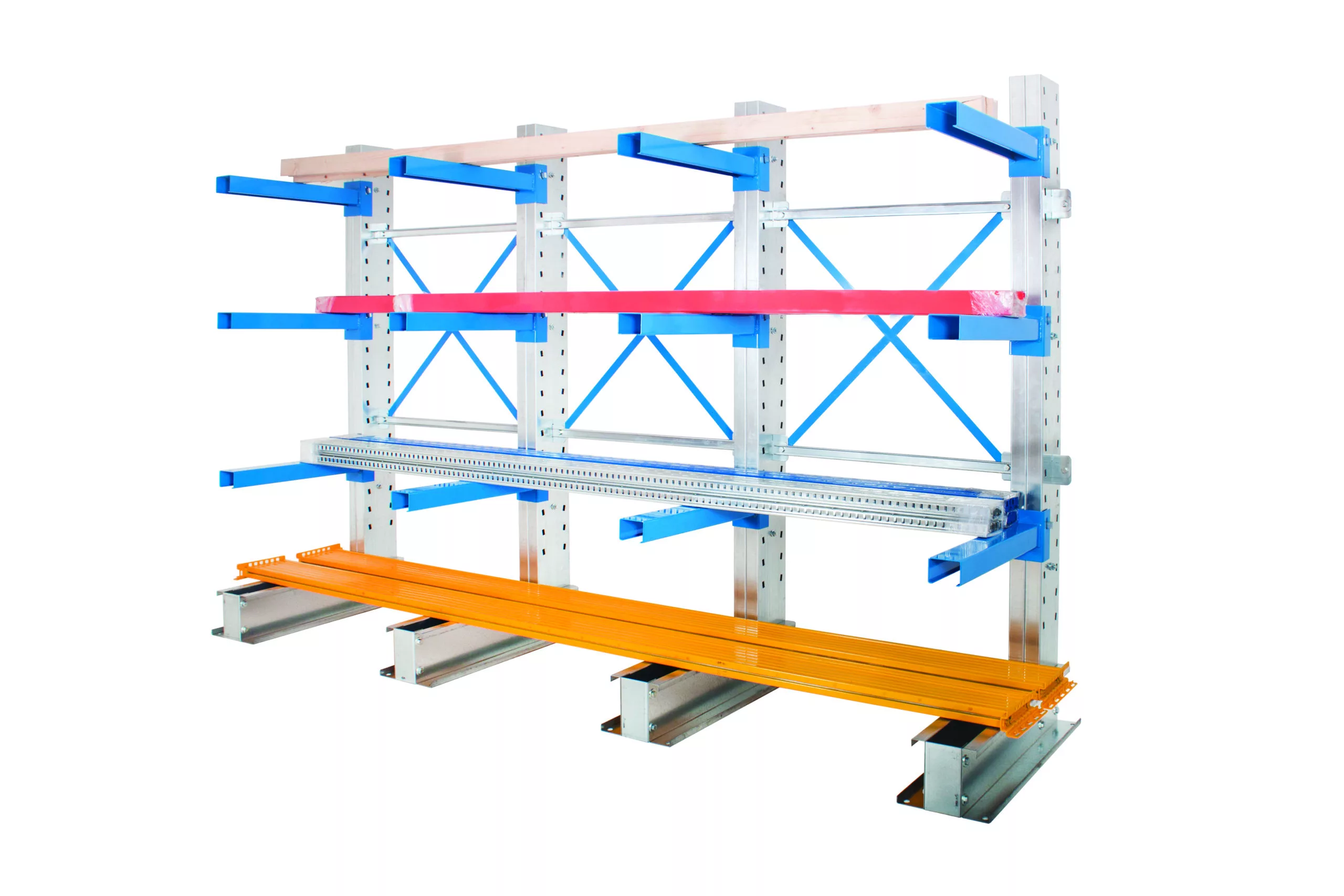

Ideal for storing:

- Timber / Wood

- Extrusions

- Steel Sections

- Long Pipes

- Timber Packs

- Scrap Vehicles

- Worktops

- Concrete Lintels

Builders Merchants

Our galvanised cantilever racking is the perfect solution for external retail display, helping you organise bulk items quickly and easily.

No front uprights ensures free, unhindered access to products with greater accuracy in stock selection.

Even on small sites, vertical storage ensures as much capacity as possible is utilised.

Retaining pins or stops can be installed to secure stock in place, such as piping and timber.

Outdoor Cantilever Racking

The galvanised finish protects the racking for long-term outdoor use.

Cantilever Racking for Timber Yards

Poor storage conditions can degrade the quality of stored timber.

Racking prevents moisture damage, allowing air flow through stock, and unhindered stock access allowing regular rotation.

Galvanised cantilever racking ensures year round outdoor protection against all weather.

Up to 10m uprights ensures you can store timber with ease and confidence.

Industrial Yards

Case study of how cantilever racking created valuable space on a previously untidy, poorly utilised working site.

The tidying of the site through cantilever racking helped boost the impression of the company to visiting clients.

Through the creation of organised work flows, greater control can be gained over production processes. This can reduce costs and increase work flow speeds, ultimately leading to healthier profit margins.

Special Racking Applications

Cantilever racking can be customised to your exact requirement. Below are just some of the possibilities that can be achieved.

Canopies

Canopies can be installed to protect wood or sensitive items from rainwater. Standalone storage buildings with cladding can also be constructed.

Car Storage Racking

Other applications include scrap car storage, providing an optimised operation process.

The high weight loading of cantilever means cars can be stored with confidence, while retaining easy access for salvaging spares.

Vehicles can be stacked up to 4 high, or 6 meters in height, either single or double sided.

Storing cars vertically ensures a tidy, safe site is kept at all times, hugely reducing the risk of accidental damage to valuable stock.

Painted

Power coated finishes are available in a wide range of colours, helping organise stock and aiding visual management. Most colours can be achieved.

Self Contained Buildings

Cladded free standing enclosures with access canopies hides stock out of sight, protecting it from the elements.

Customisation

Cantilever Racking can be fully customised based on application.

For example:

- Left to Right Ties for pallet racking

- Product retaining end stops

- Product retaining pins

- With Canopy

- With Cladding

- Plastic insert to arm end

- Flush edged top arms for delicate products

- Tyre Guards and guidance rails for forklifts

- Lintel rails for storage of items on base

What is Cantilever Racking?

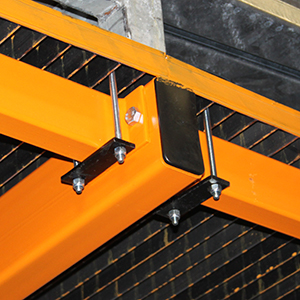

Cantilever Base

All cantilever racking requires high quality fixings on a strong base. Depending on the area and suitability, a specially made base material may need to be laid to ensure long term safety.

A site survey may be required to determine the load bearing capacity of the underlying ground strata. An additional spacing of 200mm on all sides of the racking is required to prevent cracking from expanding bolts.

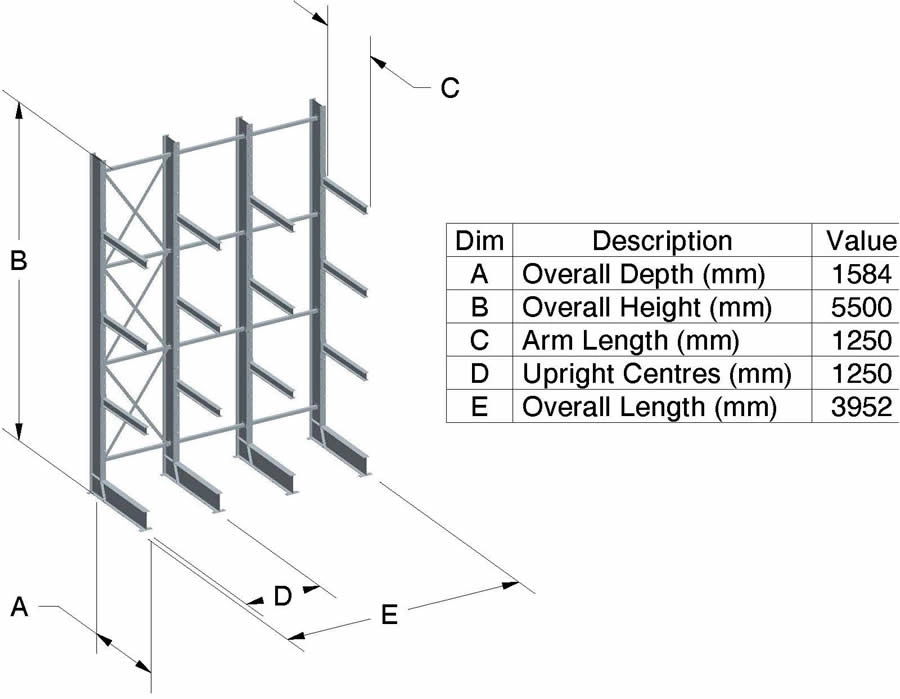

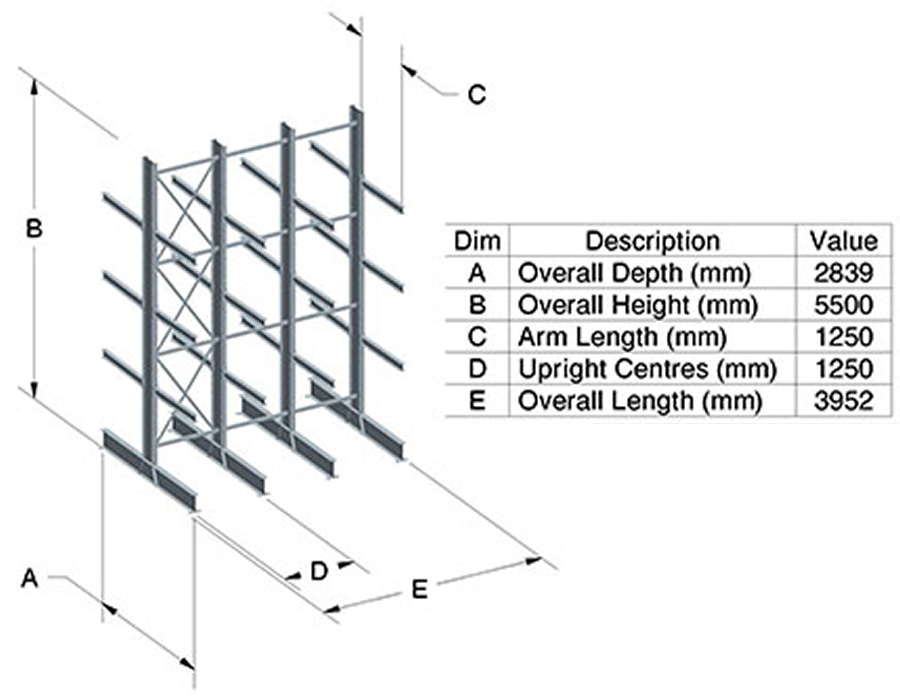

Cantilever Diagram

Please click below to enlarge a diagram explaining the system design in further detail.

**Please note, every project is unique and information supplied will vary on a case by case basis. For fully accurate information specific to your application, please contact us.

Example – Pipe storage

We were approached by a welding solutions company looking to store lengths of piping, up to 12.2 Meters in length.

Due to the large size and weight of the items, cantilever racking was a perfect solution.

Items being stored weight up to 3 tonnes per length in groups of 6 – 18 tonnes in total.

Stakrak’s high quality cantilever was able to handle high loads that competitors were not.

Arms with a length of 1250mm provide amble storage, with retaining pins keeping piping in place.

Light Duty Cantilever Racking

Delivery just 5 days from stock!

Please be advised that from immediate effect there will be a 10% price increase on these products.

Please email the office for new prices at sales@stakrak.co.uk

We also offer a range of cost effective cantilever racking, for lightweight warehouse, lumber yard and retail applications.

- Up to 2200KG Frame Load

- Up to 600KG Arm load

- Arms adjust every 70mm

- Blue RAL5015 Epoxy finish

- 3 Arms per frame

A modular system, our lightweight cantilever offers up to 2200KG load capacity in heights of 1976, 2432 or 2964mm.

Widths are available at 1000, 1500 with bolted X-braces available.